Want to know how to measure a box dimensions?

Look no further;

Our packaging expert with more than a decade of experience will teach you how to measure the dimensions of the box in less than a minute.

Why Should You Listen To Us?

Studies by the Packaging Institute reveal that a significant portion (around 37%) of businesses incur increased costs due to inaccurate packaging measurements.

We hope you understand why reading this article can save you millions.

Although measuring a box seems very simple regarding customized packaging, even the slightest miscalculation can lead to substantial financial losses.

Measuring an accurate dimension will help you calculate the exact requirement of materials, COP ( Cost of Production ), shipping charges, and more. To help you with that, we have prepared a step-by-step guide on “ how to measure a box for shipping. “We have also included graphics, videos, and expert tips.

Quick Summary

To measure a box, you need a ruler and a measuring tape. Now, measure the box’s length, width, and height and multiply them.

Note: Listed dimensions are always inside the box.

Step 1: Length is always the longest side of the box, with flaps.

Step 2: The box’s width has shorter flaps than the length.

Step 3: Height is the only dimension without flaps and measured without flaps.

Calculation: Length x Width x Height

Why Box Measurement Matters?

Research by the International E-commerce Packaging Council (IEPC) suggests inaccurate box measurements can contribute to higher product return rates. Too large boxes can lead to product movement during transit, potentially causing damage. Conversely, too small boxes can create tight fits, making removing items without damaging them difficult.

Customized boxes are a free marketing tool for your business, providing customers with a premium unboxing experience. In addition, they act as a brand ambassador of your brand in front of customers.

The slightest miscalculation while calculating the dimensions of your packaging will lead to lost packaging, which leads to damaged products while shipping. Your product passes through many hands before reaching the final consumers, and you want to avoid a dancing product in your packaging.

There are several reasons why measurement is very essential for your brand, such as:

- Determining The Amount Of Space: Measuring the box’s length, width, and height will help you calculate the space your box takes during shipping. This will allow you to estimate how many boxes you can put in a delivery truck.

- Calculating The Shipping Charges: Most shipping companies calculate the shipping charges based on the size and weight of the box. Knowing these factors can help you quickly get an estimate of shipping charges.

- To Fit On Store Shelves: If you sell your products at the retail store, making your box fit on the retail shelves is essential. Most retail stores prefer not to put a big box on their displays.

Understanding Box Dimensions, Length, Width, and Height

If you are wondering “how to measure the length, width, and height of a box, ” stay tuned. Before ordering, you must know what length, width, and height are referred to in the packaging. There are dimensions used to measure a box. Let’s discuss each of them one by one:

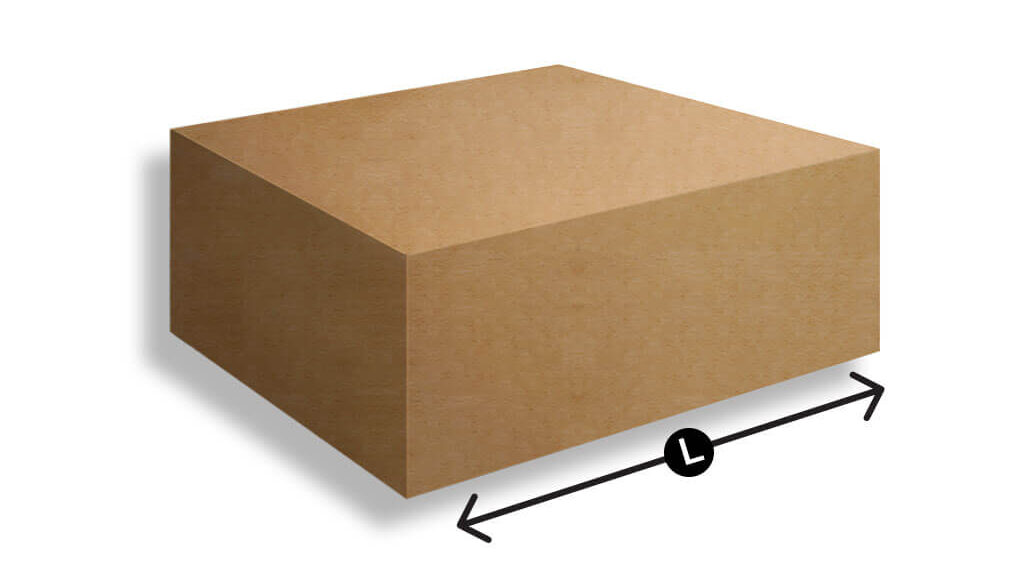

Length

If you look at the box, its longest side is referred to as its length. It also has the most extended flaps attached to it. Below, you can see an illustration of it.

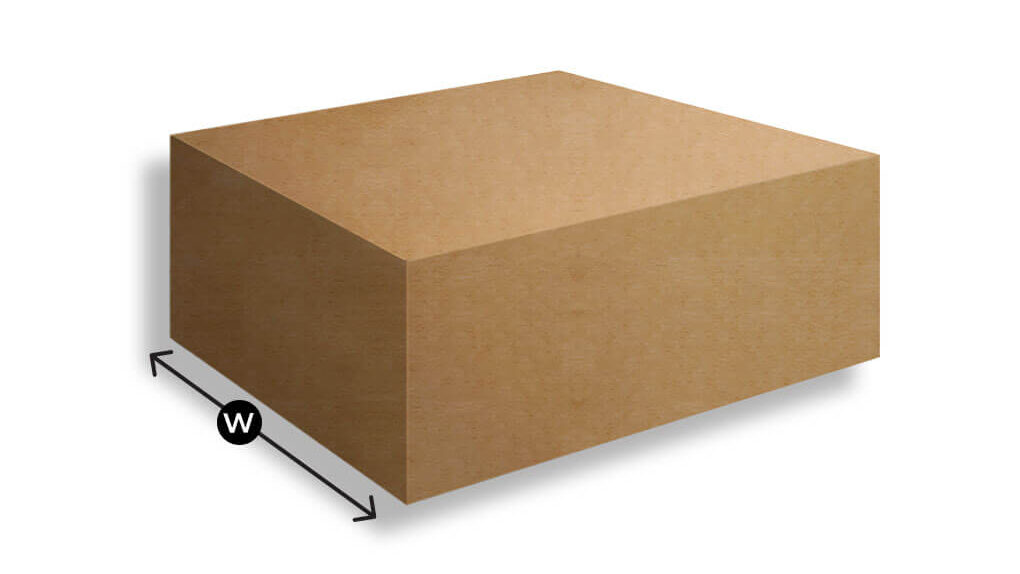

Width

If you look at the box, its shortest side is called its width. It also has the least extended flaps attached to it. Below, you can see an illustration of it.

Height ( Depth )

If you look at the box, its side perpendicular to its length and width is known as its height or depth. Speaking loosely, you can quickly identify depth because it does not have flaps.

Remember, each box has its length, width, and depth. So, before ordering, you must ensure you have the exact dimensions of your desired packaging. For your convenience, we have included some dimensions of different box styles so that you can make an educated guess.

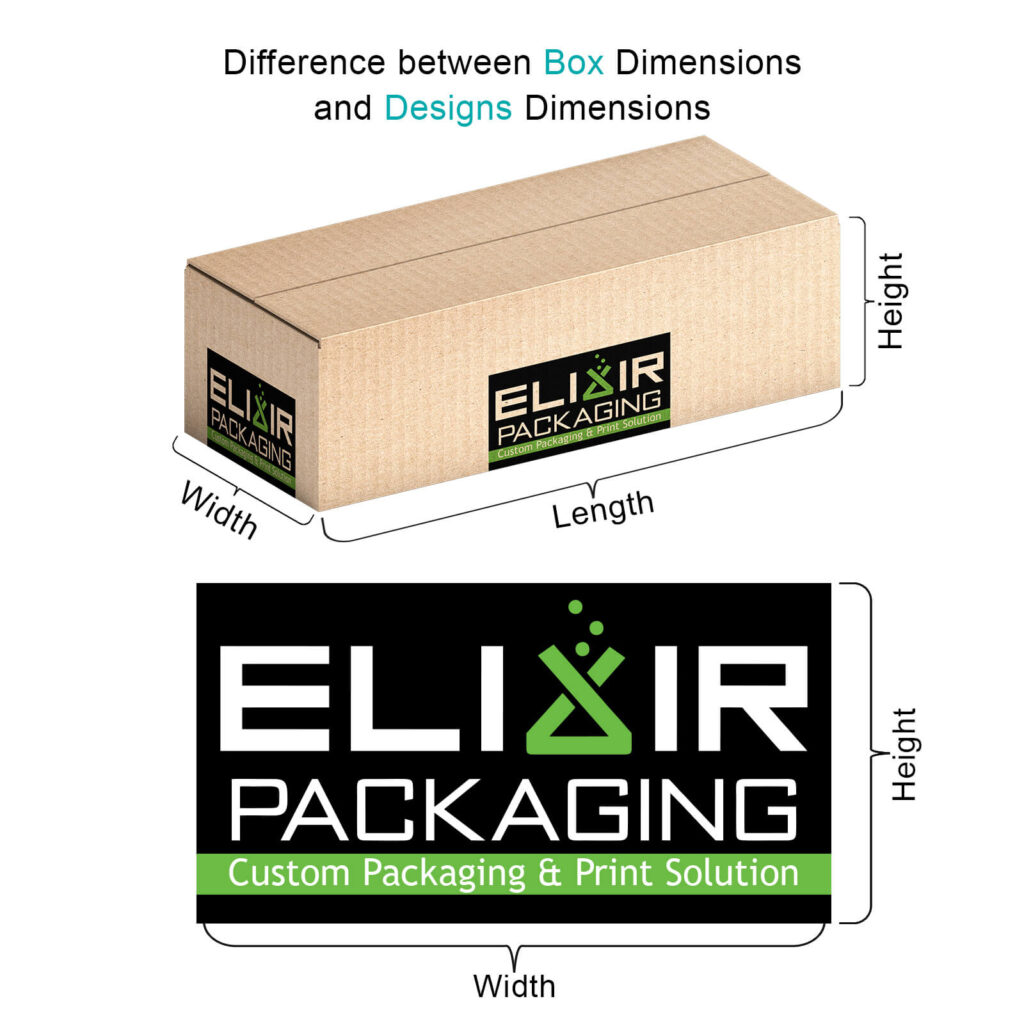

2D Packaging Designs Mockups

2-D stands for two-dimensional. In 2D design, we have only two elements: width and height.

Note: Laymen often consider length and height in 2D designs to be corrected.

Here are some examples of 2D Packaging design mockups:

Design & Illustration:

Layman’s Dimensions

Envelope Dimensions:

3D Packaging Design Mockups

To get 3D packaging mockups, you must first understand how to measure a box’s length, width, and height.

In 3D design mockups, we have the box’s length, width, and height. In most scenarios, we use 3D mockups. If you receive 3 numbers from us, you must remember that the first number represents length, the second width, and the third height.

Sounds simple, isn’t it?

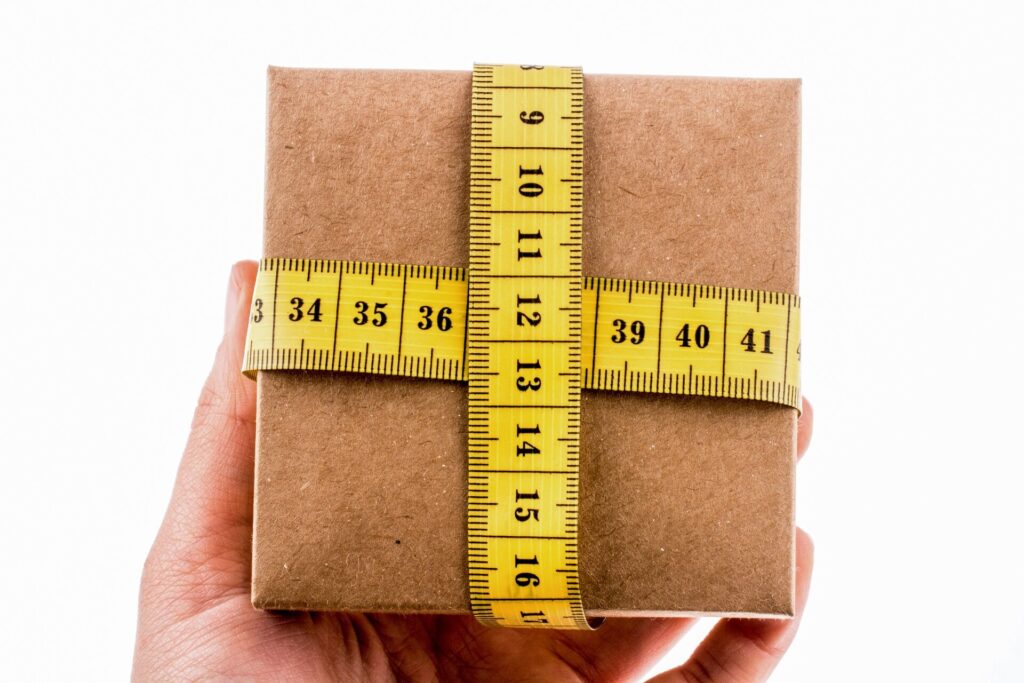

Tools Required For The Measurement Of Packaging

If you want to know how to measure the girth of a box first, you need to get tools first. Choosing the wrong tools can cost you millions. Wondering Why?

Scientific research by the American Society for Testing and Materials (ASTM) has established specific test methods (e.g., ASTM D643) to determine the “empty box compression ratio”.

This ratio indicates how much a box can deform under its weight before collapsing. Understanding this ratio helps ensure boxes maintain their shape during storage and transportation. So, you have to measure the box accurately with the right tools, such as a ruler or measuring tape.

How To Measure Box & Packaging Dimensions?

Measuring the dimensions of a box for shipping is very simple and easy all you need to do is follow these quick and easy steps, and you are good to go.

Step 1: Place A Box On A Flat Surface

Place a box on a flat surface and keep its open side facing upward. This will make your process relatively more straightforward. Grab a ruler or a measuring tape, as well as a notebook and pen.

Step 2: Measure the Inside of a Box

To measure inside the box, first, you must understand its length, width, and height.

Measuring Length: Open a measuring tape and place it inside the box. Ensure the tape starting metal tip touches the box and then stretch it towards the adjusted corners. You can guess that the longest side of the box is its length.

Measuring the width: Open a measuring tape and place it inside the box. Ensure the tape starting metal tip touches the box and then stretch it towards the adjusted corners. Remember, the shortest side of the box is its width.

Measuring the Height/Depth: Open a measuring tape and place it inside the box. Make sure the tape starting metal tip touches the box’s parallel crease, and then stretch it towards the adjusted corners. Depth can be easily measured when the tape or ruler is placed at the corner side of the box.

Step 3: Measuring the Outside of The Box

Measuring the box from the inside is relatively harder compared to the outside. That is why most people prefer to measure a box from the outside.

Studies by the International Paperboard Industry Association (PBWC) have shown that corrugated cardboard’s flute structure (the wavy layers) significantly impacts its strength. A single-wall box with a B-flute (thinner waves) offers lower stacking strength compared to a double-wall box with a C-flute (thicker waves)

Note: Dimensions of the box may differ while measuring it from inside and outside because of its stock.

Measuring Length: Hold your measurement tape along with the longest outer side of the box. Keep your tape attached to the box as shown in the image for the most accurate measurement.

Measuring the Width: Hold your measurement tape along with the shortest outer side of the box. Keep your tape attached to the box as shown in the image for the most accurate measurement.

Measuring the Height/Depth: Hold the tip of the tape measure against the bottom of the box, along any side, and extend the tape up to the open top.

Step 4: Take Careful Measurement

Now, you have to record your measurements. As long as you are precise, you don’t have to worry. Remember, boxes with rounded corners are slightly hard to measure, and their result may vary by 1/10 cm or 1/16 inches.

- Issues With External Dimensions

Now you understand how to list box measurements from both inside and outside. However, you must know there will be different results if you measure internal and external box dimensions.

Note: The industry standard for box measurement is internal, not external dimensions.

Knowing the exact internal dimensions can help you get the proper custom packaging for your product. This is helpful for you and us.

Inaccurate box measurements can make items too loose or tight inside the packaging. Loose items can be damaged during transit due to shifting, while tight fits can cause product damage during packing or unpacking. This is very important for the measurement of corrugated boxes.

How To Calculate The Volume Of The Box?

Want to know how to measure the volume of a box? It is straightforward and can be done in less than a minute. All you need to do is follow the simple steps mentioned below.

Step 1:

Before we measure a box’s volume, it is essential to know whether you need to calculate it or not. Calculating the box’s volume is essential if you are packaging items that flow like sand. Volume is measured in cubic cm, cubic inches, and cubic feet.

Step 2:

You need your response in cubic inches if you use a square box. Calculating the volume of the box and its dimensions requires the same formula. All you need to do is multiply the box’s length, width, and height.

Suppose your box is 10 inches long, 10 inches wide, and 10 inches high. Its volume would be 1000 cubic inches. You can use any online calculator to calculate this.

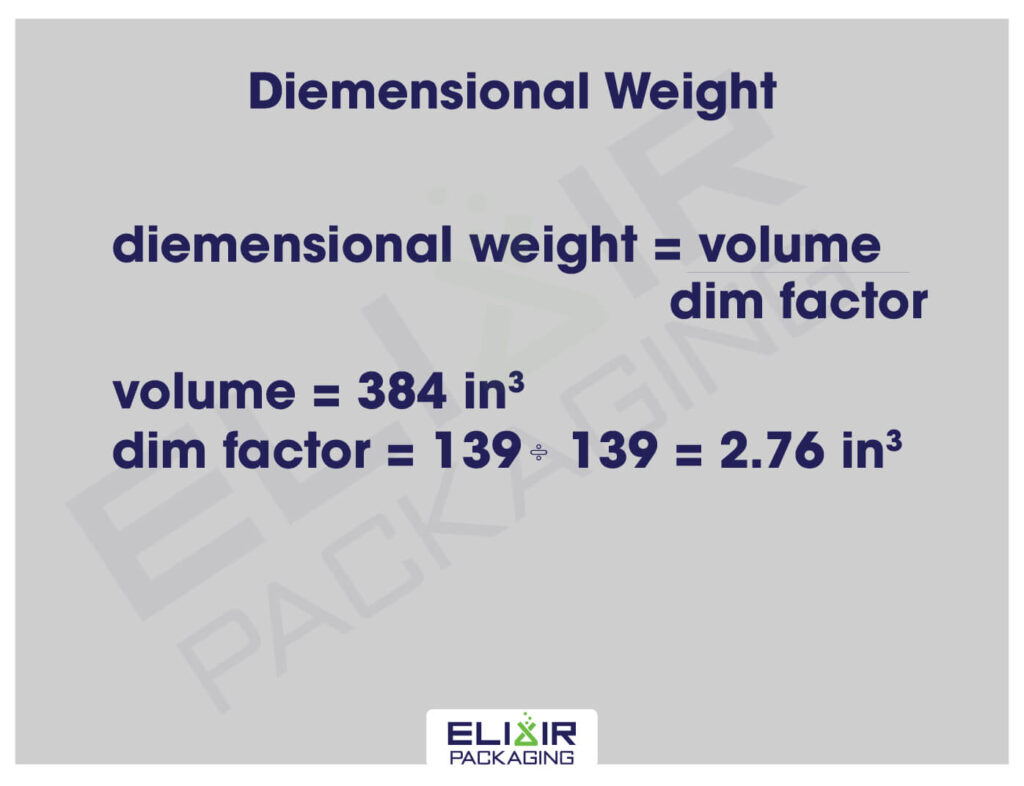

Calculating Actual Volume vs Actual Weight vs. Dimensional Weight

According to data from shipping insurance agencies, roughly 27% of complaints about damaged goods are linked to inadequate packaging dimensions.

This data clearly shows that knowing the dimensions is essential in packaging design. In my career as a packaging expert, I have seen that most people don’t know the difference between actual weight and dimensional weight, and that is why they give the wrong requirements and receive lousy packaging.

Research published in the Journal of Applied Packaging Research explores “stacking compression strength.” This refers to the maximum weight a box can withstand when stacked upon other boxes. Knowing a box’s stacking compression strength is crucial for storage and transportation, as exceeding this limit can lead to box collapse and product damage.

Actual Volume

Actual Weight

Dimensional Weight

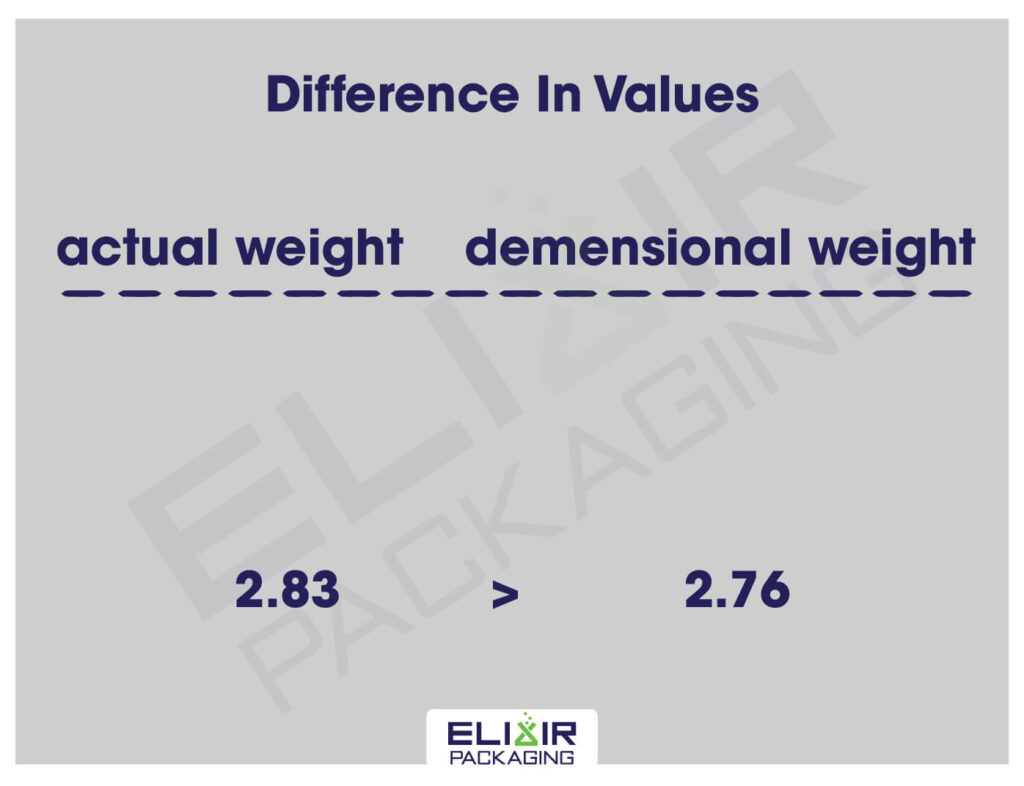

Difference In Values

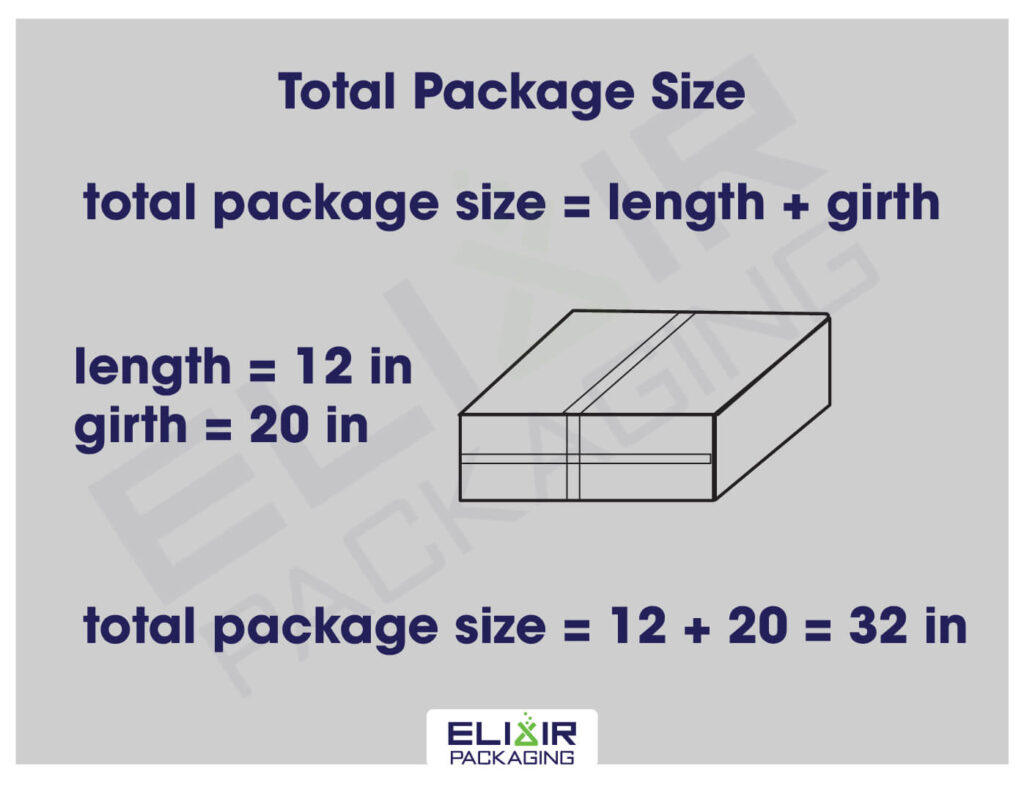

Finding the Girth and Total Size of a Package

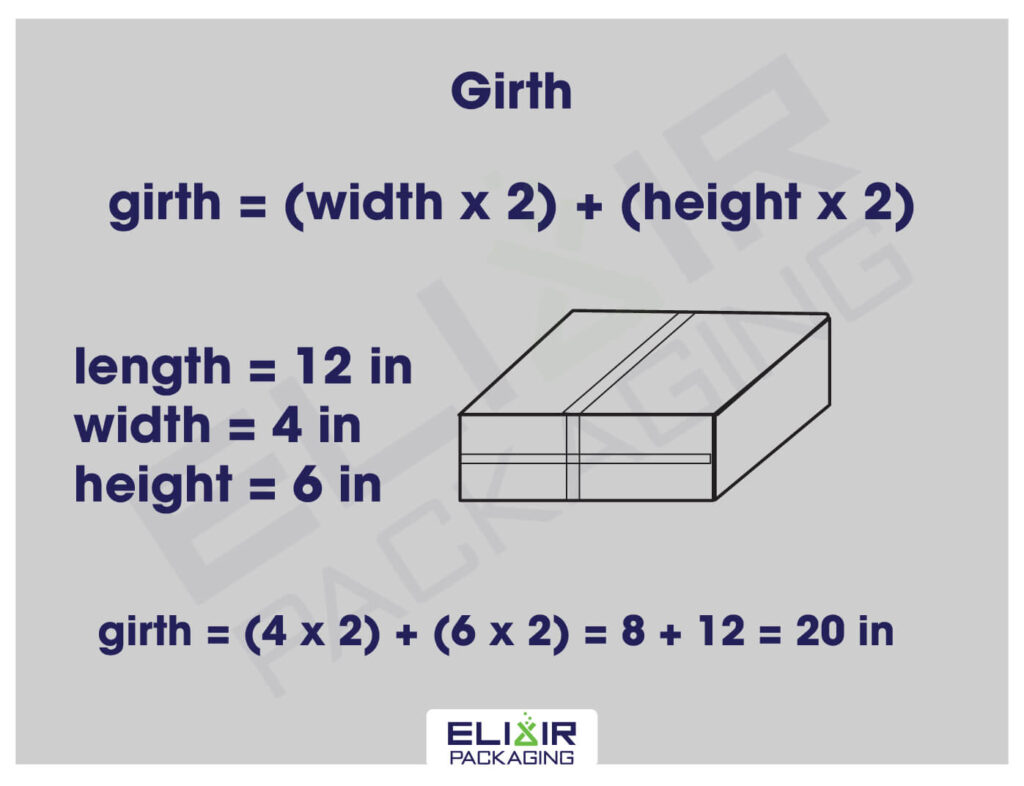

Gridth measures the distance around the widest part of the box or circumference. Finding the girth is very simple, and you can easily do this with the help of the images we have attached below.

Girth

Total Package Size

How To Measure Different Types Of Boxes?

Now, we hope you understand how to measure the dimensions of a box.

Different shipping carriers have specific package size limitations. Failing to meet these requirements due to inaccurate measurements can result in shipment delays, rejections, or additional fees.

This is why you must know how to measure different styles of boxes. Below, you can see different styles of packaging boxes along with height, weight, and length. If you are still facing any issues, don’t worry. You can contact our customer service department, and they can help you with that.

The American Society of Packaging Engineers highlights that even a minor improvement (1%) in measurement accuracy can translate to a 2-3% reduction in shipping costs.

This showcases the direct impact of accurate measurements on streamlining shipping processes.

Why Choose Elixir Packaging For Your Custom Packaging Needs?

First, we would like to congratulate you because now you will never need to search for how to measure dimensions of a box in your lifetime. After all, we have already covered everything that you need to know.

Precise box dimensions allow selecting the perfect size, minimizing wasted space and packing materials. This translates to environmental and economic benefits.

Whether running an e-commerce store or a retail shop, storing spaces can take a considerable chunk of your profit.

Accurate box measurements are crucial for optimizing storage space in warehouses or retail settings. Knowing the exact dimensions allows you to maximize storage capacity and minimize wasted space.

At Elixir Packaging, we offer a 360-degree solution for all your packaging needs. With our industry experts, you can accomplish anything you desire and easily increase your sales.

Free Design Support

At Elixir Packaging, we believe in collaborating with businesses. That is why we have hired a team of graphic designers with more than a decade of experience in your industry. With the help of our industry experts and graphic designers, you can create innovative packaging designs that can crush your competition.

Starting From 10 Boxes

We are proud to say that Our Minimum Order Quantity is so low that you can start from 10 boxes, giving you the confidence to order more. This customized packaging provides a proven result of growth in sales.

Quick Turn Around Time

As a business owner, we understand how significant the time is for you during sales season. That is why we offer the fastest turnaround time in the industry. You can get your custom-printed boxes at your doorstep within 5 to 7 business days.

Free Shipping & Low Price Guarantee

To help small businesses and startups like you, we offer free shipping. We understand shipping is costly for companies, but we are here to help you. Wait, the party isn’t over; you can buy these custom packaging wholesale. In addition, we offer massive discounts on first-time orders.

Bibliography

- American Society of Packaging Engineers (ASPE) (2016). Impact of Measurement Accuracy on Shipping Costs. Packaging Engineering 37(4): 123-128.

- Author, David (2024). Improper box dimensions can cause items to shift during transportation, potentially damaging the product.

- Li, C., & Zhang, W. (2022). An Analysis of Damaged Goods Claims in the Shipping Industry. Journal of Supply Chain Management 18(2): 54-69.

- National Retail Federation (NRF) (2020). Best Practices for Warehouse Storage Optimization. New York, NY: NRF Press.

- Paperboard Packaging Council (PPC). (n.d.) Flute Profiles. https://www.webstaurantstore.com/blog/1138/types-and-sizes-of-corrugated-boxes.html.

- Packaging Institute (2018). Annual Report. Chicago, IL: Packaging Institute Press.

- Stack, M., & Elias, N. (2018). Influence of Design Parameters on the Stacking Compression Strength of Corrugated Cardboard Boxes. Journal of Applied Packaging Research [JAPR] 7(2): 101-112.

- Industry research conducted by leading box manufacturers consistently highlights the importance of understanding a box’s ability to maintain its shape under its weight (Author, 2024).

- Smyth, D. R., & Stone, A. P. (2013). Understanding Box Dimensions: A Guide to Efficient Packaging. International Journal of Logistics Management 24(1): 17-32.

- The Influence of Accurate Box Sizing on E-commerce Return Rates, International E-commerce Packaging Council (IEPC)