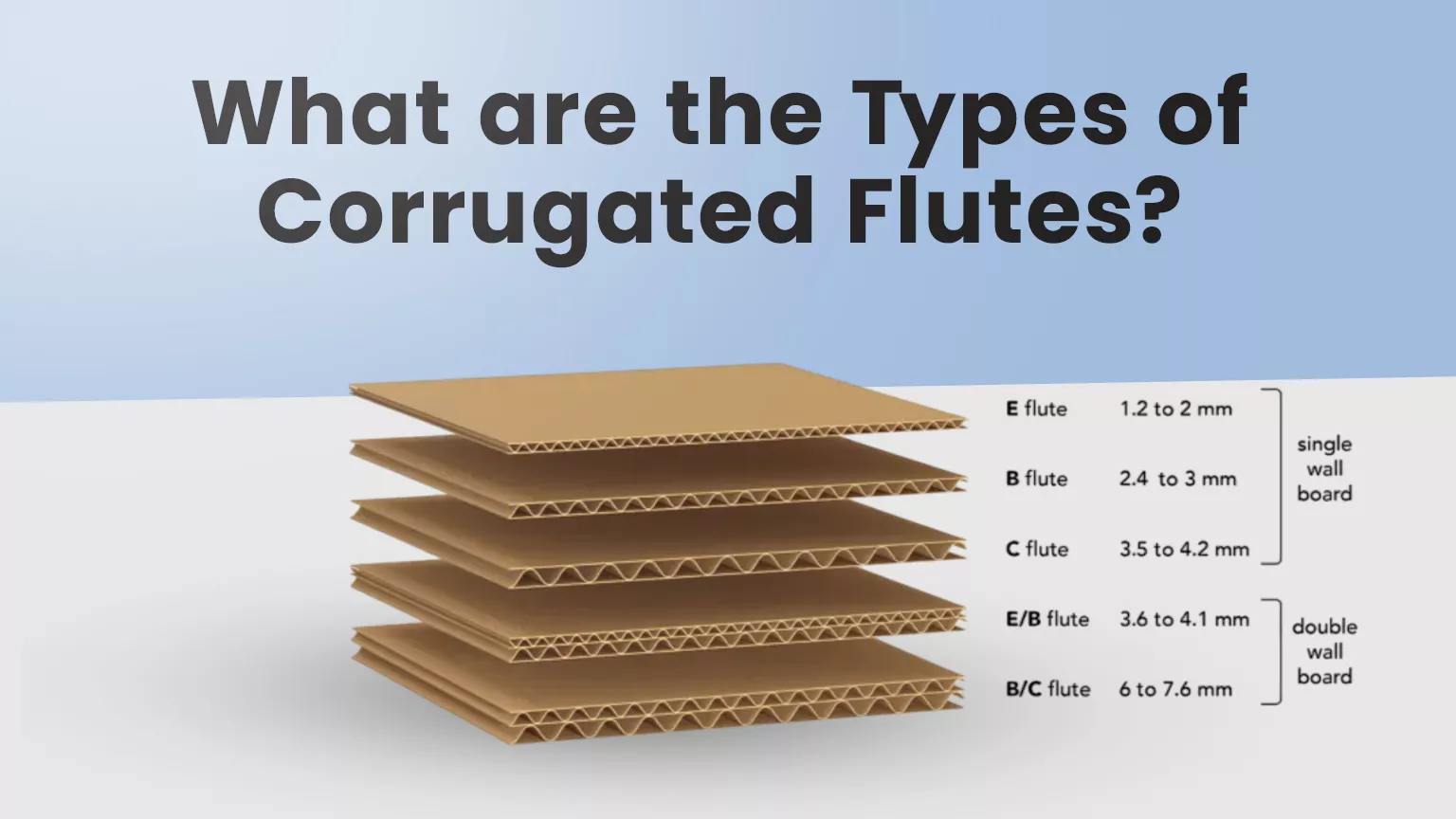

There are 5 main types of corrugated flutes: A, B, C, E, and F. All these corrugated flutes are the main components in making corrugated boxes suitable for every need.

When you think about packaging, the first material that comes to mind is probably corrugated cardboard. About 70% of businesses believe that corrugated boxes are one of the best options for packaging and shipping their products. It started being used in 1871, and until today, it’s perfect for everything from pizza boxes to shipping cartons.

But have you ever wondered what gives corrugated cardboard its strength? The secret lies in corrugated flutes. These flutes are lines that appear as wavy structures sandwiched between two paperboards or linerboards.

In this guide, we’ll break down everything about corrugated flutes so you can understand how to choose the right type for your packaging needs.

What Are Corrugated Flutes in Corrugated Boxes?

A flute in corrugated cardboard is the wavy and arch-shaped layer you see between two flat sheets (liners). These layers are part of the overall corrugated structure discussed in our main guide on what corrugated boxes are. Upon tearing, you can see the wavy structure that basically provides the strength to the box itself. These flutes act like a cushion protecting the contents of a box from impact, compression, and vibration during shipping. Each flute type is identified by a letter such as A, B, C, E, or F.

Different Types of Corrugated Flutes

Corrugated cardboard comes with different types of flutes, which are the wavy layers inside that make the cardboard strong and protective.

A Corrugated Flute

The A flute is the thickest, about 1/4 inch tall, and has fewer waves per foot. It gives the best cushioning, making it perfect for protecting fragile and heavy items during shipping. It can absorb shocks and keep delicate products safe, but its surface is not very smooth for detailed printing.

B Corrugated Flute

The B flute is thinner, about 1/8 inch tall, with more waves packed closely together. This makes the surface flatter and better for printing logos and designs. It is also strong against crushing and punctures, so it is often used inside boxes for extra protection or for packaging canned goods and beverages.

C Corrugated Flute

The C flute is the most commonly used flute, around 3/16 inch tall, which makes a good balance between cushioning and stacking strength. It is often chosen for shipping boxes because it protects products well and supports stacking. The surface is still good enough for printing branding on the box.

E Corrugated Flute

The E flute is much thinner, about 1/16 inch, with many small waves, making the cardboard smoother and less bulky. It is ideal for retail packaging where good printing and appearance matter, especially for smaller consumer products. Its thin profile helps reduce storage space and costs.

F Corrugated Flute

Finally, the F flute is the thinnest, about 1/32 inch tall, with very fine waves. This flute type provides an ultra-smooth surface perfect for high-quality printing and folding. It is commonly used for luxury or specialty packaging like cosmetics and jewelry, where a sleek look is critical.

Each flute type has different thickness, wave count, cushioning, and printability, so the right choice depends on the item’s fragility, shipping needs, and branding requirements.

| Flute Type | Flutes per Foot (Approx.) | Thickness (mm) | Key Features | Common Uses |

| A Flute | 33 | 4.8 – 5.0 mm | Great cushioning with high stacking strength | Fragile or heavy products |

| B Flute | 47 | 2.5 – 3.0 mm | Good crush resistance and compact | Retail packaging and canned goods |

| C Flute | 38 | 3.5 – 4.0 mm | Keeps a balance between strength and printability | Shipping boxes & standard cartons |

| E Flute | 90 | 1.0 – 1.8 mm | Thin and have a smooth surface for printing | Folding cartons and cosmetic packaging |

| F Flute | 125 | 0.8 mm | Very fine and ideal for small boxes | Retail display boxes and luxury packaging |

Corrugated cardboard also comes in combined or double-wall flutes, such as BC and EB flutes. These are also employed in the manufacturing of corrugated boxes, such as:

BC Corrugated Flutes

The BC flute is a double-wall board that layers the B flute and the C flute together, resulting in a thickness of about 6 to 7 mm. This combination provides excellent strength and cushioning, making it ideal for packaging that needs high protection during shipping. It generally has a basic print surface.

Comparison of B Flute vs C Flute

The B and C flutes, when combined, create a stronger corrugated structure. The table below shows the role of each flute type and how their combination enhances durability and protection.

| Feature | B Flute | C flute |

| Thickness | 2.5–3.0 mm | 3.5–4.0 mm |

| Strength | Moderate | High |

| Print Surface | Smooth | Slightly rougher |

| Best For | Retail boxes and display boxes | Shipping and storage boxes |

EB corrugated Flutes

The EB flute is another double-wall style, combining the thin E flute and the thicker B flute, with a thickness of around 4.5 mm. This adds both good printability from the E flute and strong protection from the B flute.

Comparison of E Flute vs B Flute

The E and B flutes, when combined, create a stronger corrugated structure. The table below shows the role of each flute type and how their combination enhances durability and protection.

| Feature | E Flute | B Flute |

| Thickness | 1.0–1.8 mm | 2.5–3.0 mm |

| Strength | Excellent | Good |

| Print Surface | Moderate | High |

| Best For | Printed retail packaging | Protective product packaging |

These combined flute types allow packaging manufacturers to customize strength and appearance to suit specific shipping, handling, and marketing needs by layering different flute sizes.

Corrugated Flutes Types Thickness Chart for Understanding

Each flute is different from the others, and its thickness determines the actual strength and durability of the resulting boxes. So before ordering, make sure you have a clear understanding of the standard thickness.

The table below will clear all your doubts regarding the thickness of each corrugated flute in millimeters and inches.

| Flute Type | Approximate Size Thickness (mm) | Approximate Size Thickness (inches) |

| A Flute | 4.8 – 5.0 mm | 0.19 – 0.20 in |

| B Flute | 2.5 – 3.0 mm | 0.10 – 0.12 in |

| C Flute | 3.5 – 4.0 mm | 0.14 – 0.16 in |

| E Flute | 1.0 – 1.8 mm | 0.04 – 0.07 in |

| F Flute | 1.0 – 1.8 mm | 0.03 in |

Choosing the Right Flute Type for Your Brand and Industry

If your brand is opting for custom corrugated boxes to sell your products with more protection, make sure to partner with a trusted supplier first. After that, check certifications such as FSC certification and whether they follow the SDGs of packaging as well.

Once verified, choose the box style with the relevant flute that best fits your needs. Here’s a quick guide to help you select the proper corrugated flute for your packaging project:

| Purpose | Recommended Flute Type | Reason |

| Shipping heavy items | C Flute | Excellent strength and cushioning |

| Display or retail packaging | B or E Flute | Smooth surface and neat look |

| Custom printed boxes | E or F Flute | Fine surface for detailed printing |

| Fragile products | A or C Flute | Strong protection and stacking power |

| Lightweight goods | E Flute | Sleek and cost-effective |

Right Wall Type Aligns with the Corrugated Flutes for Functionality

Corrugated cardboard comes in three wall types: single-wall, double-wall, and triple-wall.

- Single-wall has one corrugated flute layer between two flat liners, commonly using A, B, C, E, or F flutes for basic strength and cushioning.

- Double-wall has two flute layers, like BC or EB combinations, giving extra strength for heavier or fragile items.

- Triple-wall combines three flute layers for maximum durability in heavy-duty shipping boxes.

This alignment of flute types within wall structures ensures the right balance of protection, stacking strength, and printability for different packaging needs.

Conclusion

Corrugated flutes play a vital role in maintaining the integrity and strength of boxes. As a result, they provide better protection during shipping and transportation. Make sure to choose the correct flute type for your boxes to ensure durability, safety, and performance.

FAQS

What is a flute in corrugated?

A flute is the wavy middle layer in corrugated cardboard that provides strength, cushioning, and structure to the box.

What is the strongest corrugated flute?

A flute is the strongest because of its large and thick arches, offering superior stacking and cushioning ability.

How thick is the E flute corrugated?

The E flute thickness typically ranges between 1.0 mm and 1.8 mm.

What is the purpose of corrugated flutes?

Corrugated flutes provide strength, cushioning, and structural support to protect products during shipping and handling.