Corrugated boxes are multi-layer containers made from corrugated fiberboard. These boxes have wavy and fluted layers that are sandwiched between flat sheets of paper called linerboard. This unique “sandwich” construction provides strength, cushioning, and shock absorption. Making corrugated boxes ideal for packaging, protecting, and transporting products.

The North American corrugated packaging market was valued at around $41.48 billion in 2025 and is expected to grow further in the coming years. This study shows that 95% of businesses use corrugated boxes in e-commerce and packaging. Whether for shipping or transporting goods from one place to another, corrugated boxes are the most commonly used containers.

What Exactly Are Corrugated Boxes?

A corrugated box is a container made from three layers of material, such as two flat outer layers and a wavy inner layer called fluting. The fluting provides strength and protection and has a thickness of approximately 1 mm to 15 mm. These boxes are widely used for shipping because they are strong, lightweight, and durable.

Corrugated Cardboard vs. Cardboard Boxes

There is constant debate, and many people get confused about whether corrugated and cardboard boxes are the same. But that’s not true at all. There is a clear difference between cardboard and corrugated boxes:

| Corrugated Cardboard Boxes | Corrugated cardboard has three layers, such a two flat outer sheets and a wavy middle sheet that makes it strong and good for heavy items.The waves in corrugated cardboard act like a cushion to protect things inside from bumps and pressure. |

| Cardboard Boxes | Cardboard boxes are made from a single flat sheet, which is thinner and better suited for light items like shoe boxes.Cardboard boxes are easier to bend and break, so they are mostly used for things that don’t need much protection. |

History of Development of Corrugated Boxes

Corrugated packaging has its roots stretching back over a hundred years, initially developed to help preserve and store items for longer durations.

The journey began in 1856 when English inventors Healey and Allen created a method for making corrugated paper using a pair of fluted rollers and a manually operated device. Their goal was to produce a wavy paper insert for hats, not for shipping goods.

However, it was Albert S. Jones from the United States who first thought to use corrugated paper as protective wrapping for delicate objects such as bottles. His approach marked the evolution toward today’s corrugated packaging industry, where such material is widely used to shield products during transport.

What Does “Corrugated Box” Mean?

The “corrugated” part refers to the wavy (fluted) inner layer bonded between linerboards. When people say “cardboard box,” they often mean a corrugated box in shipping or packaging contexts. But technically, “cardboard” is a broader term that can include paperboard, chipboard, or rigid board, and all are different materials.

How Are Corrugated Boxes Made in Simple Steps?

The process of making the corrugated boxes uses large machines, some over 300 feet long and strict quality control to make boxes strong and tailored to customer needs. But the whole processing of these boxes is done in simple steps, such as:

- First, the softwood trees like pine are cut down and made into wood chips.

- These chips are ground or cooked with special chemicals to make pulp, which becomes the base for paper.

- The pulp is turned into two types of paper, such as flat sheets called linerboard and wavy sheets called medium.

- The medium is specially made to be fluted or ruffled for strength.

- Then a large machine called a corrugator presses the medium between rollers to form flutes (the wavy part).

- Then, after that, the hot steam shapes the flutes, and glue is applied on each side.

- The corrugator then attaches a flat linerboard to each side of the fluted medium using a starch-based adhesive, creating a strong sandwich called corrugated board.

- The corrugated board is cut into sheets of the right size, and fold lines called scores are added for easy folding.

- Finally, the sheets are folded into box shapes and glued, stapled, or taped at the seams, making the final boxes ready for use.

What Is the Structure of a Corrugated Box?

Corrugated boxes are made up of material grades composition such as:

- Linerboard: The flat outer layers of the box.

- Fluting: The wavy middle layer that provides cushioning and strength.

- Medium: The paper used to create the fluting.

This sandwich construction gives corrugated boxes their durability and protective qualities.

Types of Corrugated Walls for Strength

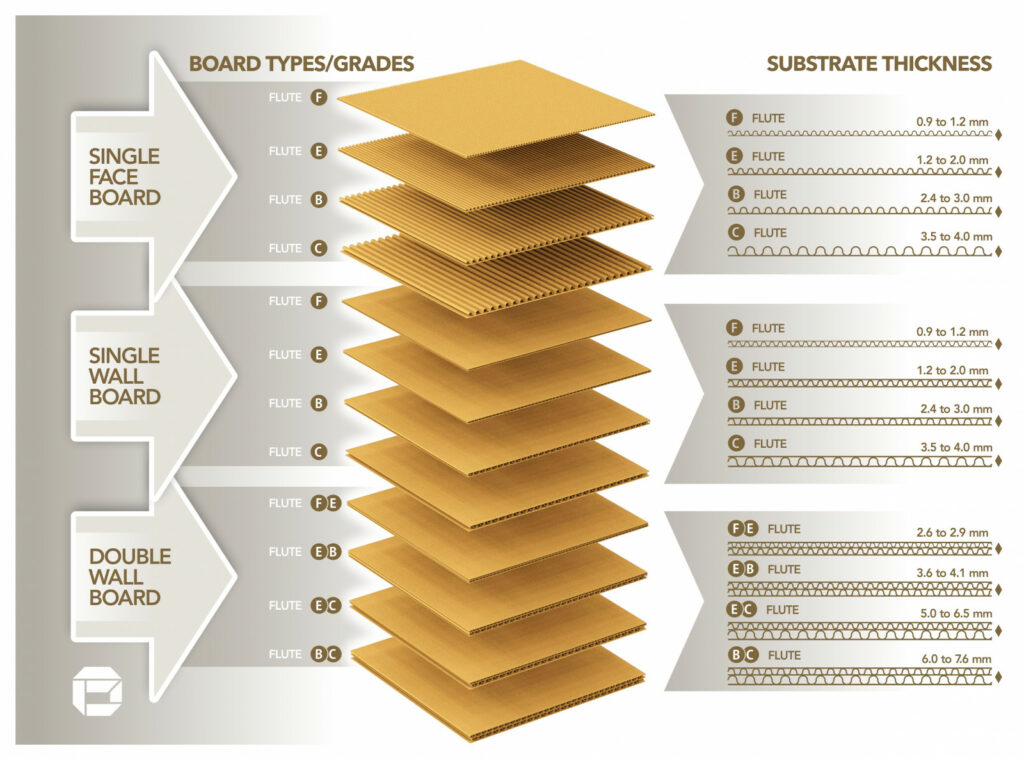

Corrugated board grades describe the thickness and strength of the board, depending on the type of paper used for the liners and the number of fluting layers.

- Single Wall: One layer of fluting between two linerboards that is suitable for medium-strength needs. Its thickness is 3/16 inch (4.8 mm).

- Double Wall: Two layers of fluting between three liners that provide extra strength for heavier or fragile items. Its thickness is 5/16 inch (7.9 mm).

- Triple Wall: Three layers of fluting with four liners that offer the highest strength for very heavy loads. Its thickness is 7/16 inch (11.1 mm).

Higher-grade boards are ideal for bulkier or delicate goods requiring extra cushioning and resistance during shipping.

Types of Corrugated Flutes

When you tear a corrugated box, you’ll notice the wavy paper inside; these are the corrugated flutes that make the box stronger. There are certain types of flutes in corrugated boxes.

- A-Flute: The thickest is about 1/4 inch. It offers the best shock absorption and stacking strength, perfect for delicate or heavy goods.

- B-Flute: It is about 1/8 inch thick. Moreover, it resists punctures well and provides a smooth surface for printing, often used in retail packaging.

- C-Flute: It is around 5/32 inch thick. It provides a balanced choice for strength and print quality, widely used for shipping cartons and fragile items.

- E-Flute: It is roughly 1/16 inch thick. It provides a very smooth surface for high-quality printing, common in cosmetics and electronics packaging.

- F-Flute: The finest and smallest one that is about 1/32 inch thick. It is ideal for luxury and small folding cartons requiring a sleek look.

For a detailed explanation of each flute type, including their thickness, strength, and best uses, read our complete guide on types of corrugated flutes.

Each flute type has a unique thickness and purpose to suit different packaging and printing needs. Below is the corrugated board grade chart:

Examples & Styles of Corrugated Boxes You Can Opt For

Choosing the right corrugated box style is important to ensure products fit snugly without moving inside. Common styles include:

- Regular Slotted Container (RSC)

- Full Overlap Container (FOL)

- One-Piece Folder Box

- Tab Lock Roll End

- More

Certifications and Testing of Corrugated Boxes

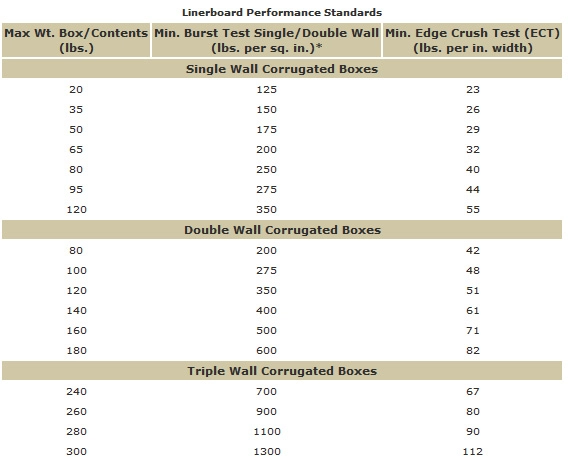

When buying custom corrugated boxes, confirm that manufacturers test them for strength using methods like the Mullen Burst Test and Edge Crush Test (ECT).

- Edge Crush Test (ECT): Measures how much vertical pressure the edges can handle before deforming. Results are reported in kiloNewtons per meter (kN/m).

- Mullen Burst Test: Tests the board’s resistance to bursting by applying pressure until rupture, measured in pounds per square inch (psi).

Boxes with higher ECT values are better for stacking, while higher Mullen values ensure impact resistance. Moreover, always check the box maker’s certificate for added transparency.

Benefits of Corrugated Boxes

There are endless benefits of corrugated boxes, such as:

| Benefits | Description |

| Protection of Goods | The fluted middle layer provides cushioning that absorbs shocks and prevents damage to fragile products. |

| Cost-Effective | They are affordable to produce making them economical for businesses. |

| Customizable | Corrugated boxes can be easily tailored in size, shape and printing allowing brands to create packaging. |

Ready to Make an Informed Decision?

There are many manufacturers of corrugated boxes, but we at Elixir Packaging are different and offer custom corrugated boxes with full customization options. Contact us now to get your queries solved right on time.

FAQS

Are corrugated boxes recyclable?

Yes, the corrugated boxes are made from recyclable materials and can be recycled after use.

Can corrugated boxes be customized?

Yes, corrugated boxes can be tailored to specific sizes, shapes, and branding needs.

Are corrugated boxes waterproof?

While corrugated boxes offer some moisture resistance, they are not waterproof. For items requiring full moisture protection, additional treatments or coatings may be necessary.