Quick Summary: Ethylene vinyl acetate foam also known as Eva foam is a high-density foam that is used to make inserts for customized packaging. This foam material is mostly used to protect fragile products like electronics, glass, etc.

What Is Ethylene Vinyl Acetate Foam?

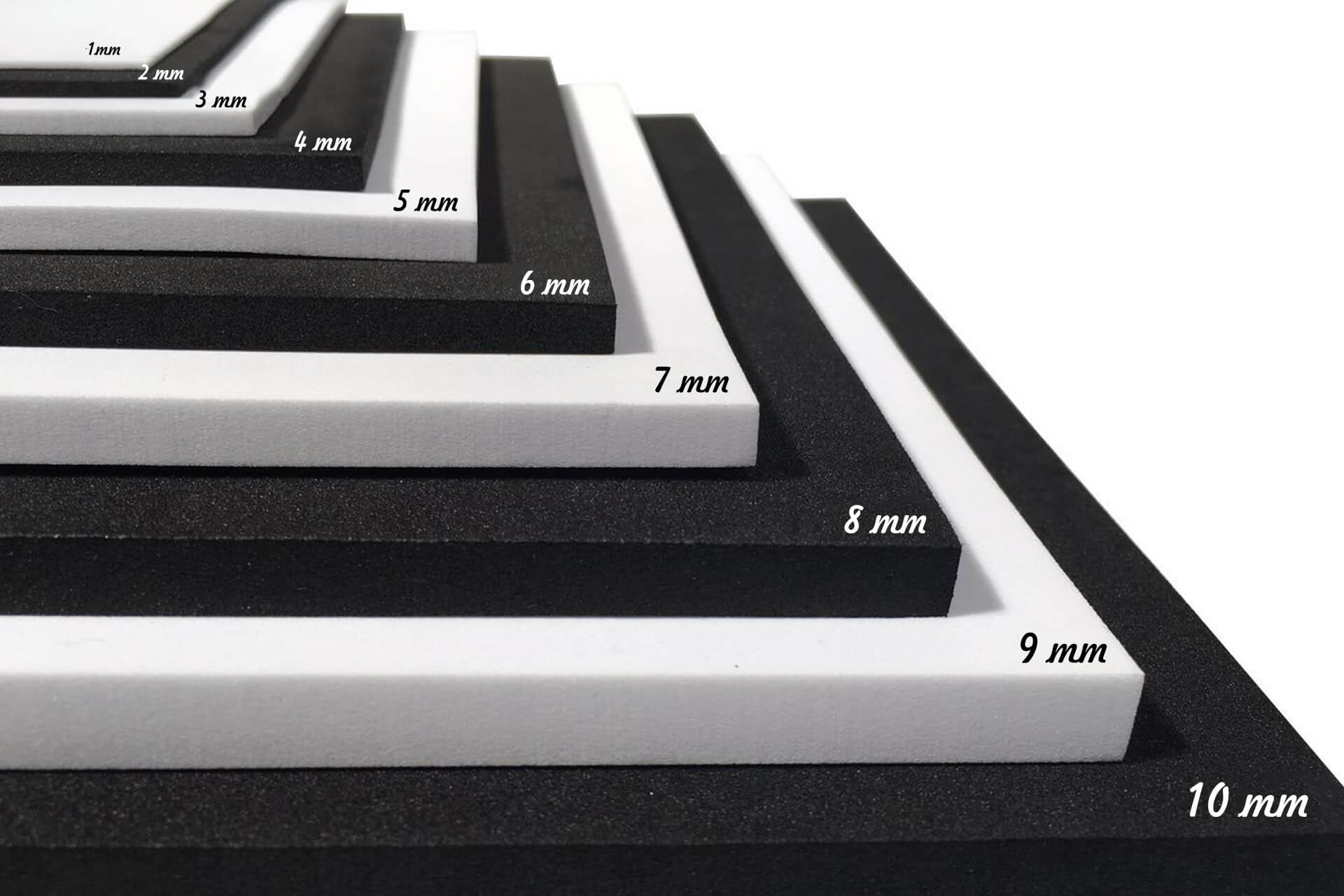

Ethylene Vinyl Acetate foam is a thick foam that is used for the packaging of fragile luxury goods. It is used to protect your luxury goods during shipping from shocks, vibrations, etc. Compared to other foams like EPE or PU, this ethylene vinyl acetate foam is very preferred by multiple industries because it can be molded into any shape and size. That is why it is preferred to provide support to your products and keep them intact. Our EVA foam comes in different colors and densities so you can choose the right fit according to your needs and requirements.

What Are Some Key Features Of Ethylene-Vinyl Acetate Foam?

There are several features of ethylene-vinyl eva foam such as:

- This foam is dense and protects your goods during shipping.

- This foam provides excellent support to your products and keeps them stable.

- This foam provides high-impact resistance.

- This foam can be designed and molded according to your products.

- This foam is super lightweight which reduces shipping costs.

- The foam is super elastic and offers great flexibility.

- This foam can be used as a substitute for natural rubber, vinyl, neoprene, polyurethane and PVC foams, wood composites, felts, fiberglass, and mineral wool.

EVA Foam Fabrication Methods

Different methods are used for ethylene-vinyl acetate foam fabrication such as:

- Water Jet Cut: This process is used to cut foams with high-pressure water. It is preferred when you need to get extremely sharp shapes and edges.

- Router Cut: This method is mostly used at the prototyping stage not at the finished stage due to its rough edges.

- Die-Cut: This process is used to cut foams with a series of dies and it is ideal for 2D cutouts.

- Wire-Cut: This process is used to cut foam with a heated wire. It melts the foam and vaporizes it leaving smooth and crisp cuts.

Laser Cut: This process is used to cut foam with a laser that vaporizes the foam and leaves smooth edges.

Ethylene-vinyl acetate Foam Finishes

| Name | Explanation |

| Ethylene-Vinyl Acetate Foam Flocking | This is done by applying a fiber powder on EVA foam through which we can obtain a sense of soft touch. |

| Ethylene-vinyl acetate Paperboard Lamination | This is done by pasting a paperboard on top of EVA foam. |

PU vs EPE vs EVA: Foam Comparison

| Foam Name | Density (kg/cm³) | Hardness | Overall Weight | Available Colors |

| Polyurethane Foam (PU) | 18 – 45 kg/m³ | 38/45/60 Shore C | Light | Black, White, Grey, Yellow |

| Polyethylene Foam (EPE) | 20 – 120 kg/m³ | 30 – 38 Shore C | Light | Black, White, Pink |

| Ethylene-Vinyl Acetate Foam (EVA) | 33 – 280 kg/m³ | 15 – 80 Shore C | Heavy | Black, White |